what objects are made from and how they came to be

* essays in the form of imagined narratives carry a light yellow background

The smoldering heat was almost unbearable. The blacksmith dripped with sweat as he monitored the vapor tendrils rising from the crucible that he had packed with copper and zinc ores. Impatient with waiting for the two metals to form the desired brass, he turned to finish the other portion of his project: a set of fine cosmetic spatulas that he hoped to sell to the wife of a guardsmen stationed on the edge of Caesarea Philippi, at the small outpost of Tel Anafa.

The broad-shouldered man was rather pleased with the change in metal styles brought by the recent Roman military presence in this region. Many people now preferred the new bright glossy hue of their pins and rings, and the golden color of his alloy would definitely add to the popularity of these implements as well.[1] The smith didn’t care for himself – he would make whatever sold well – but he did appreciate how relaxed the cementation process was for forging this Roman-type brass: just one part zinc for every four parts copper. Orichalcum, they called it. Then he reminded himself: I’ll have to make a separate set for the Jewish villagers in Galilee. They were not likely to buy such obviously Roman-looking goods,[2] even less so now, given the rumors he was hearing about the recent execution of the Jewish teacher from Nazareth.

The boiling liquid brought him out of his distracted thoughts. Turning back to his furnace, he removed the closed crucible from the heat. It was time to cast the molten brass and finish the rest of the set of spatulas. With practiced hands, he carefully poured the vibrant orange liquid from the crucible into the mold. A promising journey – and sale – awaited.

[1] Matthew J. Ponting, “Chemical analysis of copper-alloy metalwork from the Roman contexts. In Tel Anafa II, ii, pp. 287-298.

[2] Matthew J. Ponting, “Keeping Up with the Romans? Romanisation and copper alloys in First Revolt Palestine,” Journal of the Institute of Archaeometallurgical Studies 22 (2002), pp. 3-6.

The bead-like pendant that is attached to the hoop of the earring was cast using a two part mold comprised of two leaves.[1] Half of the pendant is carved into each of two leaves of a mold, possibly made of tuff or other easily worked stone. The seam is still visible where the two halves of the mold touched. The line runs along the vertical axis of the beads on the bottom of the earring. In this case the beads were then fused to the hoop, although examples of ancient two part molds that also include the hoop are known from Cyprus. Methods like casting would have made this earring easily reproducible and thus more affordable. Fusion, like casting, would have involved the use of a small furnace, bellows, and tuyeres (blowpipes to raise the temperature of the furnace). Fusion however requires that the temperature of the furnace be raised to the point where the two jewelry elements meld together but not high enough for the silver to melt, and indicates a complete control over the heat source. The hoops to which the beads were fused could have been cast themselves, or forged using hammers or rocks into the desired shape.

[1] Merker in TA II, ii, pp. 250-251.

Before glassblowing was invented in approximately 50 B.C., ancient glassmakers sometimes made glass vessels through the process of core-forming, a technique developed nearly 1,600 years earlier.[1] The process involves forming a clay or mud core in the shape of the intended vessel around a metal rod. Glass was then applied to the core, although scholars disagree about exactly how this was done. Strands of hot glass may have been trailed onto the core and then rolled or “marvered” on a stone surface to smooth it out, or the core may have been dipped into molten glass or rolled in a paste of powdered glass and then heated. Strands of glass in different colors were then trailed on, and a tool could be dragged through the strands to form patterns. The shaped vessel was removed from the core and cooled, and then the core was scraped out, leaving a hollow interior.[2]

[1] “Pivotal Moments in Ancient Glass,” The Toledo Museum of Art, accessed November 28, 2017, http://www.toledomuseum.org/kiosk/ancient-asian-european-glass/ancient-glass/pivotal-moments-in-ancient-glass/.

[2] David Grose, “Ancient Glass,” Museum News, The Toledo Museum of Art, Toledo, Ohio 20, no. 3 (1978), 31; “All About Glass | Corning Museum of Glass,” Corning Museum of Glass, accessed November 28, 2017, https://www.cmog.org/video/core-formed-vase-technique.

The fragment of mammal long-bone had been carefully worked. No thicker than the finger of a girl, perhaps the metapodial or radius of a young, wild deer was selected from the refuse of an evening meal.[1] Long slender foreleg bones enabled the animal to leap and move swiftly in the Galilee hills—though in this case, not quickly enough. Once the bone was scraped clean of meat, it was boiled and set in the sun to dry. Still, the cortical surface was smooth and waxy; its freshness ensured that each end could be sawn off without splintering. Fine incisions, cut with a metal blade, ringed the shaft like joints. Between these, the blade scratched faint diagonal lines, joining them like netting. A terracotta whorl could be specially made to fit snugly, wedged up against the tapered end of the bone. Unlike a heavy wood spindles, this light bone tool spun the airy fleece into delicate yarn. The first lengths of thread would be urged along in the diagonal incisions until they gathered and wound against the rings, marking out progress. Once the spindle bulged thick with yarn, the whorl was pulled free and set aside. The spindle carried on working, wending over and under the warps of the loom, yielding its creation over the horizon of weave.

[1] Redding in TA I, i, p. 289.

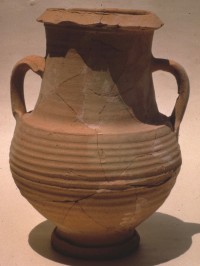

The even horizontal ridges around this vessel’s globular lower body show that it was made on a wheel: the potter formed the vessel by slowly pulling the clay upwards, with one hand on either side of the vessel walls.[1] The ridges stand out against the smooth edges of the columnar neck; a join between these areas (visible on the interior) suggests that the vessel was made in two pieces. The handles at the neck and body reflect the hand that formed and attached them. This vessel, which was used for serving wine, is called a table amphora: ‘amphora’ because it has two handles, and ‘table’ because its sturdy foot and small size make it suitable for setting on a table.[2] The wide neck and angled rim offer a perfect fit for the bronze strainers that would sit atop and be used to decant wine at the table.[3] The shape is inspired by contemporary Parthian glazed vessels, but the mineralogical make-up of the clay body show that the place of manufacture was the southern Phoenician coast, probably near the city of Tyre.[4]

[1] Tony Birks, The Complete Potter’s Companion (Boston, New York, and London: Bulfinch Press, 2003), 25-9.

[2] Berlin in TA II, i, p. 39.

[3] Berlin in TA II, i, p. 21.

[4] Berlin in TA II, i, pp. 9-10, 37.

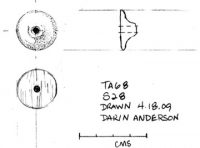

At just 4 grams, this unusual whorl is one of lightest of the 147 excavated at Tel Anafa. It is made of stone, rather than the lightweight bone more often used.[1] Spindle whorls typically feature rounded, bulbous profiles, but here the rare, concave shaping may have served to lessen its heft. Whorls act as flywheels when combined with a shaft known as a spindle. When set in motion, the momentum of turning twists strands of plant or animal fibers, smoothing the surfaces and creating greater tensile strength.[2] Small whorls such as this one work well with short stranded wool fibers, but could also have been used with longer-stranded flax. Whatever the fiber, the result would have been exceptionally fine thread.[3] The quantity of lightweight whorls excavated at the site suggests either a local preference for textiles with high thread counts or an indication that production exceeded household needs. Small, round artifacts with narrow center holes are often assumed to be beads, but here the asymmetry and flat profile may eliminate that possibility.[4] The essential characteristic of an effective whorl is the position of the shaft hole: anything off center produces uneven torque rendering it useless. [5] This whorl, intentionally carved from stone instead of shaped from malleable terracotta, is a testament to the skill required to make an efficient and elegant tool.

[1] Larson and Erdman, TA II, iii, p. 165 and p. 172, table 1.

[2] Janet Levy and Isaac Gilead, “Spinning in the 5th Millennium in the Southern Levant: Aspects of the Textile Economy,” Paléorient 38, no. 1/2 (2012): 128.

[3] Eva Andersson Strand, Textile Terminologies in the Ancient Near East and Mediterranean from the Third to the First Millennnia BC, ed. Cécile Michel and M.-L. Nosch (Oakville, CT: Oxbow Books, 2010), pp. 11–12.

[4] R.K. Liu, “Spindle Whorls: Pt. 1, Some Comments and Speculations,” The Bead Journal, no. 3 (1978), p. 98.

[5] Liu, 99; Larson and Erdman (above, n. 1), p. 160; Lindy Crewe, Spindle Whorls: A Study of Form, Function and Decoration in Prehistoric Bronze Age Cyprus, Poc edition (Jonsered: Coronet Books, 1998), pp. 11–13.

This tripod grinding bowl[1] is made from vesicular basalt, a particularly favorable material for grinding and one readily found close to Tel Anafa.[2] Basalt is an igneous (i.e., volcanic) rock; vesicular basalt is named for the vesicles, or air bubbles, that give the material its porous texture. The small holes that appear throughout the basalt form as a result of cooling lava. The hot magma cools so quickly that it hardens around the bubbles of gas within the lava, creating the characteristic small circular cavities. In use, the cavities help grab grain or other material and facilitate the grinding process.[3] Because the material maintains its porous consistency throughout, vesicular basalt remains coarse and effective even after extensive use. The holes also make this type of basalt easier to carve, and make the objects lighter and more portable.[4]

[1] Wells et al. in TA II, ii, p. 317.

[2] Vassiliou in TA II, ii, 282-4; Wells et al., in TA II, ii, p. 300.

[3] Wells et al., in TA II, ii, p. 300.

[4] Wells et al., in TA II, ii, pp. 300. 314; Jennie R. Ebeling and Yorke M. Rowan, “The Archaeology of the Daily Grind: Ground Stone Tools and Food Production in the Southern Levant,” Near Eastern Archaeology 67, no. 2 (June 2004): 108-117.